DURAGRID® Phenolic Grating

DURAGRID®DURAGRID®Phenolic Grating is often used in the oil and gas industry because of its increased fire and smoke performance. DURAGRID® Phenolic is the first composite grating to receive U.S. Coast Guard approval for use in locations and applications as allowed in the ASTM F3059 Matrix guide for fiberglass grating meeting Structural Fire Integrity Level 2 (L2). The ASTM F3059 enhances and will replace the USCG PFM 2-98 matrix.

Phenolic Grating, compared to typical polyester, vinyl ester and epoxy FRP products, offers major improvements in reduced smoke density, reduced smoke toxicity and structural fire integrity when exposed to fire. DURAGRID® Phenolic Grating complies with Annex 1 (Resolution MSC.307(88) , Part 2, 2.41 and 2.4.2 (smoke and toxicity testing) of the FTP Code (International Code for Application of Fire Test Procedures) – (MSC 88/26/ Add.2) issued by the International Maritime Organization.

Features of DURAGRID®

- Corrosion Resistant

- Structurally Strong

- High Impact and Fatigue Strength

- Lightweight

- Fire Retardant

- Easy to Fabricate and Install

- Low Maintenance

- Low Electrical and Thermal Conductivity

- Resistant to Chipping and Cracking

- Aesthetically Pleasing Appearance

- Skid Resistant

- Non-Sparking

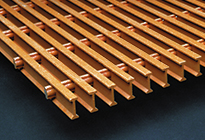

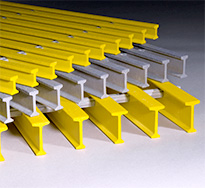

3-Piece Cross-Rod System

Strongwell’s 3-piece cross-rod system is the best assembly method for pultruded grating in the fiberglass grating industry because it provides better stability than competitive crossrod systems. The three piece members in combination with Strongwell’s proprietary bonding method tie the bearing bars together and provide stability to the grating panel. This system makes Strongwell’s pultruded grating the superior choice in the marketplace.

DURAGRID® custom grid and grating systems are designed to accommodate specific applications that cannot effectively be met by a standard fiberglass grating. DURAGRID® offers the customer options such as selection of bar spacing (which creates varying open space in the grating or grid), bar shape, cross-rod placement, custom fabrication, custom resin or color.

Fabrication

DURAGRID® gratings are lightweight and, therefore, easily handled in installation, and cost less to ship than steel grating. A patented 3-piece cross-rod system mechanically locks and chemically bonds the cross-rods to the web of each bearing bar. This separates and affixes bearing bars firmly in position and distributes concentrated loads to adjacent bars. The system allows DURAGRID® grating to be cut and fabricated like a solid sheet.